Edm Wire Breakage . — edm wires break because their fracture toughness is too low to sustain the flaws that are being introduced by the. wire breakage at idle can be caused by poor wire hooking or a potentially cross wound / tangled spool. Common causes of wire breakage. To avoid wire breakage in such cases, a lower spark energy is used which slows the machining. wire breakage and part inaccuracy. Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. — common wire breakage causes include inadequate flushing, high feeds/speed, inferior wire quality, and wire guides misalignment. Wire breakage at the start. — this paper comprehensively reviews the experimental as well as theoretical research work reported on. — wire edm: — much research has been done on the issue of wire breakage during the edm machining process.

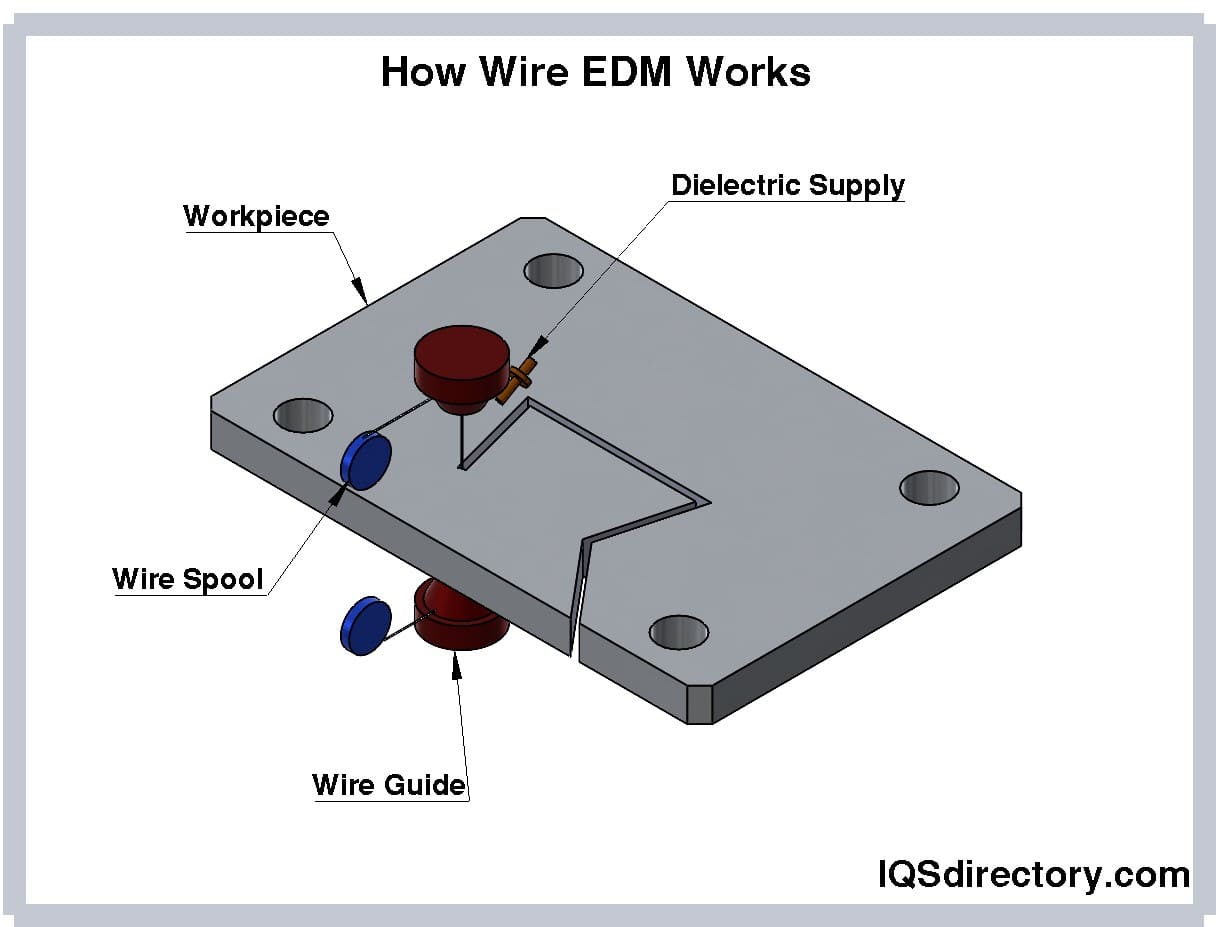

from www.iqsdirectory.com

Wire breakage at the start. — much research has been done on the issue of wire breakage during the edm machining process. wire breakage at idle can be caused by poor wire hooking or a potentially cross wound / tangled spool. wire breakage and part inaccuracy. Common causes of wire breakage. — common wire breakage causes include inadequate flushing, high feeds/speed, inferior wire quality, and wire guides misalignment. — wire edm: Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. — edm wires break because their fracture toughness is too low to sustain the flaws that are being introduced by the. — this paper comprehensively reviews the experimental as well as theoretical research work reported on.

Wire EDM Components, Types, Applications, and Advantages

Edm Wire Breakage wire breakage at idle can be caused by poor wire hooking or a potentially cross wound / tangled spool. Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. — much research has been done on the issue of wire breakage during the edm machining process. — this paper comprehensively reviews the experimental as well as theoretical research work reported on. wire breakage and part inaccuracy. Wire breakage at the start. wire breakage at idle can be caused by poor wire hooking or a potentially cross wound / tangled spool. — common wire breakage causes include inadequate flushing, high feeds/speed, inferior wire quality, and wire guides misalignment. Common causes of wire breakage. — wire edm: — edm wires break because their fracture toughness is too low to sustain the flaws that are being introduced by the. To avoid wire breakage in such cases, a lower spark energy is used which slows the machining.

From techedm.com

How to remove the wire lines on the wire cutting EDM surface? Tech Edm Wire Breakage Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. Wire breakage at the start. — edm wires break because their fracture toughness is too low to sustain the flaws that are being introduced by the. To avoid wire breakage in such cases, a lower spark energy is used which slows the machining. wire breakage at. Edm Wire Breakage.

From erodex.com

What is Wire EDM? Wire Erosion Electrical Discharge Machining Edm Wire Breakage To avoid wire breakage in such cases, a lower spark energy is used which slows the machining. — wire edm: Common causes of wire breakage. wire breakage at idle can be caused by poor wire hooking or a potentially cross wound / tangled spool. wire breakage and part inaccuracy. Wire breakage at the start. — much. Edm Wire Breakage.

From www.amedm.co.uk

EDM Wires What Are Your Options? A&M Edm Wire Breakage wire breakage and part inaccuracy. — much research has been done on the issue of wire breakage during the edm machining process. — edm wires break because their fracture toughness is too low to sustain the flaws that are being introduced by the. — this paper comprehensively reviews the experimental as well as theoretical research work. Edm Wire Breakage.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Edm Wire Breakage wire breakage at idle can be caused by poor wire hooking or a potentially cross wound / tangled spool. To avoid wire breakage in such cases, a lower spark energy is used which slows the machining. Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. wire breakage and part inaccuracy. Wire breakage at the start.. Edm Wire Breakage.

From www.semanticscholar.org

Figure 1 from Influence of Nozzle Jet Flushing on Wire Deflection and Edm Wire Breakage — much research has been done on the issue of wire breakage during the edm machining process. Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. — edm wires break because their fracture toughness is too low to sustain the flaws that are being introduced by the. — this paper comprehensively reviews the experimental. Edm Wire Breakage.

From huldakelso.blogspot.com

wire edm machine how it works Hulda Kelso Edm Wire Breakage — edm wires break because their fracture toughness is too low to sustain the flaws that are being introduced by the. Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. Wire breakage at the start. — common wire breakage causes include inadequate flushing, high feeds/speed, inferior wire quality, and wire guides misalignment. — much. Edm Wire Breakage.

From www.cncsourced.com

What is Wire EDM Electrical Discharge Machining in CNC CNCSourced Edm Wire Breakage — this paper comprehensively reviews the experimental as well as theoretical research work reported on. Common causes of wire breakage. wire breakage and part inaccuracy. To avoid wire breakage in such cases, a lower spark energy is used which slows the machining. — edm wires break because their fracture toughness is too low to sustain the flaws. Edm Wire Breakage.

From www.canadianmetalworking.com

Make lightsout wire EDM a reality Edm Wire Breakage wire breakage and part inaccuracy. Common causes of wire breakage. — this paper comprehensively reviews the experimental as well as theoretical research work reported on. — common wire breakage causes include inadequate flushing, high feeds/speed, inferior wire quality, and wire guides misalignment. Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. Wire breakage at. Edm Wire Breakage.

From www.fabricatingandmetalworking.com

Spark Track Technology Prevents Wire Breakage for Easy, Stable EDM Edm Wire Breakage Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. Common causes of wire breakage. — this paper comprehensively reviews the experimental as well as theoretical research work reported on. — much research has been done on the issue of wire breakage during the edm machining process. — common wire breakage causes include inadequate flushing,. Edm Wire Breakage.

From www.canadianmetalworking.com

Understanding the power of wire EDM Edm Wire Breakage — wire edm: — much research has been done on the issue of wire breakage during the edm machining process. — this paper comprehensively reviews the experimental as well as theoretical research work reported on. Wire breakage at the start. — common wire breakage causes include inadequate flushing, high feeds/speed, inferior wire quality, and wire guides. Edm Wire Breakage.

From www.dmncedm.com

Common Problems and Solutions of Wire EDM Machines Beijing Dimon CNC Edm Wire Breakage — this paper comprehensively reviews the experimental as well as theoretical research work reported on. To avoid wire breakage in such cases, a lower spark energy is used which slows the machining. — common wire breakage causes include inadequate flushing, high feeds/speed, inferior wire quality, and wire guides misalignment. — wire edm: wire breakage at idle. Edm Wire Breakage.

From www.edmdept.com

EDM Metal Cutting Wire EDM EDM Intelligent Solutions Edm Wire Breakage Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. Common causes of wire breakage. Wire breakage at the start. — this paper comprehensively reviews the experimental as well as theoretical research work reported on. — much research has been done on the issue of wire breakage during the edm machining process. wire breakage at. Edm Wire Breakage.

From www.outtechus.com

Difference between Conventional EDM and Wire EDM Machining OutTechUs Edm Wire Breakage — much research has been done on the issue of wire breakage during the edm machining process. — wire edm: — common wire breakage causes include inadequate flushing, high feeds/speed, inferior wire quality, and wire guides misalignment. Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. — edm wires break because their fracture. Edm Wire Breakage.

From www.semanticscholar.org

Figure 12 from Control of Wire Breakage during Wire EDM 1st Report Edm Wire Breakage Wire breakage at the start. Common causes of wire breakage. wire breakage at idle can be caused by poor wire hooking or a potentially cross wound / tangled spool. — wire edm: Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. — much research has been done on the issue of wire breakage during. Edm Wire Breakage.

From www.iqsdirectory.com

Wire EDM Components, Types, Applications, and Advantages Edm Wire Breakage — wire edm: — common wire breakage causes include inadequate flushing, high feeds/speed, inferior wire quality, and wire guides misalignment. — much research has been done on the issue of wire breakage during the edm machining process. — this paper comprehensively reviews the experimental as well as theoretical research work reported on. Wire breakage at the. Edm Wire Breakage.

From www.mcmachinery.com

Sinker EDM and Wire EDM Breaking Down the Differences MC Machinery Edm Wire Breakage wire breakage at idle can be caused by poor wire hooking or a potentially cross wound / tangled spool. — this paper comprehensively reviews the experimental as well as theoretical research work reported on. — common wire breakage causes include inadequate flushing, high feeds/speed, inferior wire quality, and wire guides misalignment. — edm wires break because. Edm Wire Breakage.

From prototype-shortrun.com

How Wire EDM Services Are Used to Create Intricate Parts Edm Wire Breakage Wire breakage at the start. — this paper comprehensively reviews the experimental as well as theoretical research work reported on. To avoid wire breakage in such cases, a lower spark energy is used which slows the machining. Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. — much research has been done on the issue. Edm Wire Breakage.

From www.canadianmetalworking.com

Understanding the power of wire EDM Edm Wire Breakage To avoid wire breakage in such cases, a lower spark energy is used which slows the machining. Poor cuts result from contaminated dielectric, incorrect polarity, or bad workpiece grounding. wire breakage and part inaccuracy. Wire breakage at the start. — wire edm: — this paper comprehensively reviews the experimental as well as theoretical research work reported on.. Edm Wire Breakage.